NEW AND NOTABLE: SIRE’S CROWN EYEWEAR

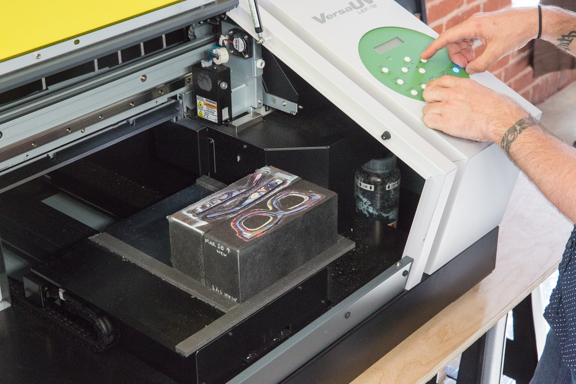

While frames made by huge manufacturers like Luxottica and Safilo under designer name licences ruled the eyewear roost for decades, online companies like Warby Parker and Eyebobs shook up the system. Since then, the space has been blown wide open. Mix in the growing attention to economic and ecological responsibility and you have Sire’s Crown. It was co-founded in 2007 by optician Chris Erven and designer CJ Thomason. Each Sire’s Crown frame is locally manufactured in Downtown LA, molded from an eco-friendly composite mixture of cotton fiber and wood pulp and then customized with thousands of options and combinations of thin wood veneer. For each frame sold, the company plants 100 trees. We caught up with co-founder Thompson to find out more.

Why eyewear, why wood and why now?

I’m a fan of functional art. I’ve always liked eyewear as a style, but I also respect the fact that without it, if you really need them, you’re screwed. We turned a weakness into a strength. I can’t tell you how often i hear “Man I wish I wore glasses!!” which is funny considering they’re basically wishing they had a handicap because all the cool kids have made that handicap awesome. Wood is gorgeous. Its natural, never looks the same, and as a naturally grown resource and with the proper protocols to make it sustainable it’s the perfect material for hand made and one-of-a-kind accessories. In this day and age, mass manufacturing is becoming an outdated source of distribution. There are cost efficient variables that will always be equated to mass manufacturing but there is also more waste and when you mess up you mess up big. Each one of our frames is hand crafted to fit the client. We do not make mistakes. Our process is extremely detailed for each and every piece. We make each frame perfectly sized and adjusted, with the perfect wood variation and grain structure, and each is protected with a sun cured finish. What sets us apart is the fact that we are basically an optical shop, but instead of buying other people’s glasses, we make them ourselves.

How important was it to manufacture in America/LA?

Its extremely important. The bottom line is that almost everything we consume comes from another country that does not have the fortunes and luxuries we do. Many work in horrible conditions for minimal pay so all the middlemen can take their cut. It’s rough. But how do you get a client to pay a premium for something made here? The coolest aspect of making your own product is your ability to innovate your product quickly. In one month we can do what would take overseas companies four to nine months: design, manufacturing, testing and shipping. We’re a small company and as we’ve grown our need to custom make every frame has only solidified our place in the American Made movement. Our company as it exists today wouldn’t make it with overseas manufacturing. It wouldn’t even be a version of our company.

What have been some of the biggest obstacles you’ve had to overcome and how did you do it?

We have dodged bullets like Neo in “The Matrix.” Our obstacles are far far too long to even begin to describe but we’re persistent, we’re passionate and we’re too stupid to know when we should stop.

How do you handle the tree planting? Where in the world? Why?

We work with Trees for the Future. They go into overcultivated regions of the world and teach them to grow sustainably with diverse farming methods and agroforestry.

What’s the business plan moving forward? Do you plan to wholesale or open stores?

We have no plans for a brick-and-mortar shop. We definitely believe virtual interaction is the future and allows us to pioneer a new way to buy glasses. Since we can custom make them we have unique ways to fit the perfect pair on each and every client by having them work with a stylist/designer face to face. We are looking into ways to install our customization platform with opticians, eyewear stores and department stores.