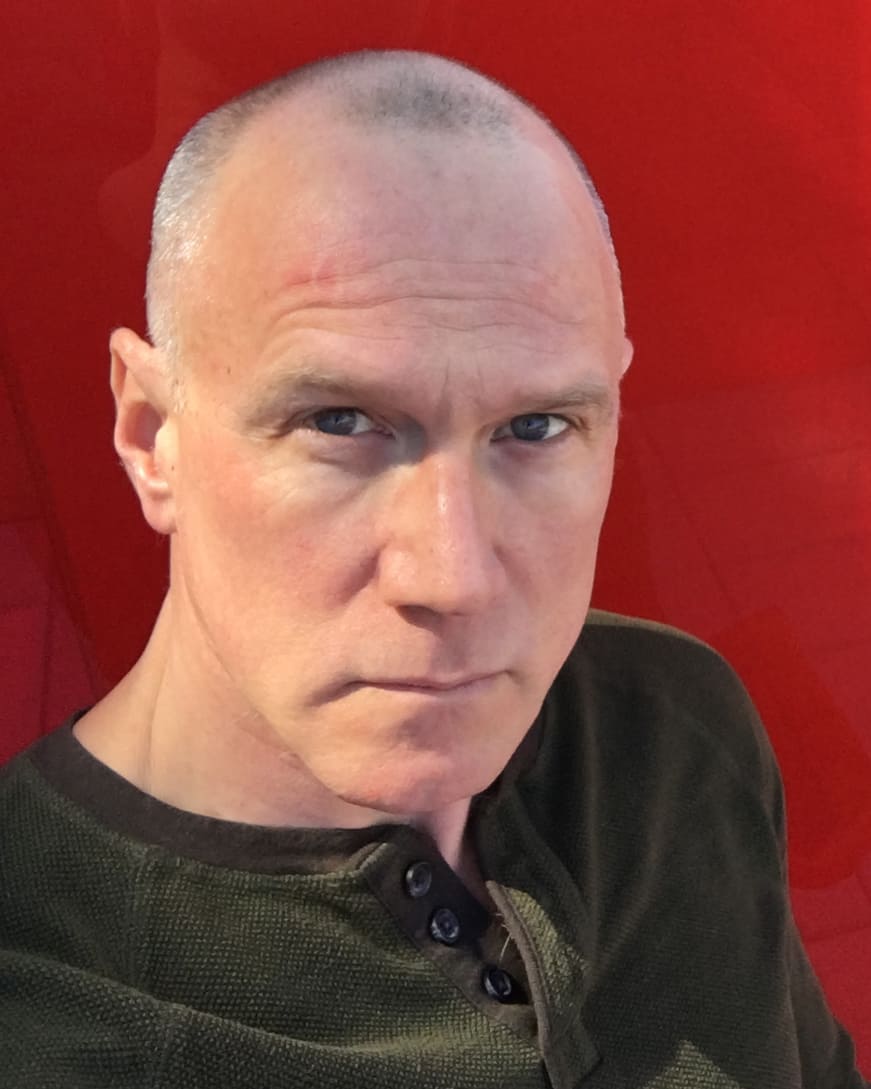

INDOCHINO ROARS AHEAD WITH CEO DREW GREEN

Made-to-measure company Indochino is confidently heading into the Roaring 2020s with plans to open its 100th store, launch women’s, and further build its partnership with Nordstrom. We caught up with entrepreneurially minded CEO Drew Green to learn about his passion for the industry.

How did you get started in this business?

“I’ve been an entrepreneur for more than 20 years. I started in technology; starting and selling my first business when I was still in university. Then I went overseas to play basketball for a while (Green played for York University in Toronto, then in Sydney, Australia for the Kings, traveling across Asia to 22 countries.), but when I came back to New York, I started a company which was sold to DoubleClick (which is now owned by Google), and then for the last 15 years have been building companies. Indochino was launched in 2008 by a couple of college students who did a great job bringing the hundreds of years old made-to-measure tradition online. My partners and I came into the business in 2015 when it was really a niche brand that had very little revenue. We’ve probably grown faster than any other apparel brand in North America over the last seven years. We’ve raised over $100 million for the business and have done nine figures in revenue for the last five years. We have almost 100 stores, with the largest made-to-measure online business in the world, and we’re just having a lot of fun building it. Now it’s global. We’ve got 800 employees in North America, and another 2,700 in China working on garments every day.”

How’s business?

“It’s insane: We just had a colossal, above record month in March. We’re about 20% above plan, and our KPIs have been up across the board for three months now. We had a very good year last year, but the last quarter was explosive. Wedding is a big part of that, but it’s also about men going back to work. Employers want folks to come back, so wardrobes need to be refreshed. We’re excited. This year is going to be special. We are going to launch our 100th store this year, and have women’s made-to-measure launching in the second half of the year.”

“I spend a lot of time talking to customers because that’s how I learn the most and how I plan the business. I feel like the casual movement is nice, but people want to get dressed up. People want to look great. The core of any man’s wardrobe is still the suit: There may be days when a leather jacket and a T-shirt are okay, but when you think about your closet, that centerpiece is a suit, whether it’s for a date, a wedding, or work. The one thing I love about Indochino is that we really make people feel better. Wearing a nice suit makes you feel more confident. When I talk to customers, they’re looking forward to getting back into it and dressing up again. Last week [end of March], we did close to $4 million, and 40% of that was wedding.”

Green expects the wedding boom to last for two or three years. “A lot of people had to cancel weddings, sometimes multiple times, due to COVID, and so I think there are going to be millions of weddings, above and beyond the average amount in a year. That’s a really good thing for this business because the millennial man loves to go to Indochino to get his suit, as well as those of his groomsmen.

That 100th store Green mentioned may just be inside a Nordstrom: the company has been working with the department store for two years and launched eight showrooms in February 2022, with another 12 launching in June and July.

“Nordstrom is a great partner, and it’s been great to work with the team there. We have a mini showroom in the men’s department, with no real inventory: Nothing’s really there except for fabrics and whatever the customers need to create their one-of-a-kind garment.”

Green anticipates growing the business to 200 or 300 stores in the next decade and believes that the alliance with the department store would not only elevate the brand but would also put it in front of new customers while bringing a new generation of millennial men into Nordstrom.

Indochino’s average price for a suit is about $450. “When I envisioned the business as an omnichannel market leader, I really wanted to understand what value was for our customers. We’ve proven that it’s the combination of an amazing experience with a great price and exceptional quality. Going to either a showroom or a website and creating a one-of-a-kind garment is fun and a little bit addictive, but price matters, right? Given the quality, we could price our garments at $600 or $700. But we’ve set up our supply chain and managed the cost elements of the business so that we can provide made-to-measure to the masses. We are essentially vertically integrated into our manufacturer, (they bought 20% of the business five and a half years ago for $30 million) so my employees are actually working in their factories

From a fashion standpoint, “Spring/Summer ‘22 is pretty bold. We’ve got bright yellows, reds and, blues and we think it’s time to get back to having some fun. It’s been an extraordinary couple of years, and I still think the 2020s are going to be a repeat of the Roaring ‘20s.

Beyond classic tailoring, the brand also offers other made-to-measure or customizable options, as well as a selection of basic knits.

“As people were working from home, not going into the office, and weddings and graduations were canceled, our shirting business just took off. We also have outerwear, which is fantastic, as well as some casual items like khakis that are made to measure. We can really round out a wardrobe.

Has Indochino been challenged by any of the supply chain issues that so much of the industry has faced?

“Everybody looks at Indochino and they see our amazing stores and our online business, and the ease and awesomeness of the website, but really, I retrenched the entire business from the supply chain out. We’ve got our factories in China that are not only a partner, they’re like family. They’re on our board. We haven’t had any disruption with the mills. We had a lot of fabric on hand when COVID hit, and we’ve been able to replenish with no problem. We’ve got a global partnership with DHL which has made things efficient. There are hiccups, but we don’t have the same supply chain issues as other companies because we’re not bringing things over to put them in a store or warehouse: We make everything one of a kind, and ship direct to the consumer, one at a time. We’ve been really fortunate and frankly, and it’s been a differentiator for us because a lot of apparel retailers have struggled with inventory and the supply chain.”

Made-to-measure shirting is an explosive category for the company. Green reports that Indochino has been seeing an incredible increase in shirt bundling, i.e., customers buying three or more shirts. 30% of shirt bundles sold online in 2021 were sold in November, but the company sold 240% more bundles in February 2022 than it did in February 2021. 57% of all shirts sold in 2021 were in bundles vs. 30% in 2020. Altogether in 2021, the company sold 81% more shirts than the previous year, and in February alone, sold 191% more shirts than last February, almost three times as much. Over the last three months, white shirts have made up over 50% of shirt sales, almost four times as much as the next most popular color, blue.

The brand currently has 120 different fabrics in stock, including 100% Cotton, a cotton/lyocell/spandex blend, and a cotton/spandex blend, as well as Spring season-specific linens and linen blends and Fall-specific cotton and wool blends. Of course, a wide range of shirt customizations are available, including dress vs. casual lengths, camp shirts, collars, cuffs, pockets, trims, monograms, etc.

What sort of technology updates can we expect to see?

“Our first major release for the year was to make any suit a tuxedo. The customer can choose any fabric that he might primarily use for a suit and make it into a tuxedo. There’s a lot of technology on the back end for us to be able to do that. Really the biggest thing this year is launching women’s made-to-measure. There are a lot of technology changes that need to happen there with the operational process, as well as the silhouettes and fabrics that we bring to market.