VENDOR VIEW: SHIFTING SUIT STRATEGIES

While tailored clothing makers have done a great job producing basic, slim-fit suits for weddings and events, most are still dealing with recent realities including mill delays of four to five weeks and shipping costs that have doubled. And, of course, the uncertainty of how long recent strong wedding/event business will continue.

That said, there are plenty of reasons for optimism. These include:

- Office re-openings after Labor Day that should inspire more dress-up. (Although according to a report by Pew Research Center, 59 percent of employees are still working remotely. Among those remote workers, 78 percent say they want to continue to work remotely after the pandemic, up from 64 percent two years earlier.)

- Increased interest in made-to-measure and customization leading to higher AURs.

- Retailers doing more business with fewer promotions, leading to higher AURs.

- Wedding venues booked for at least another year.

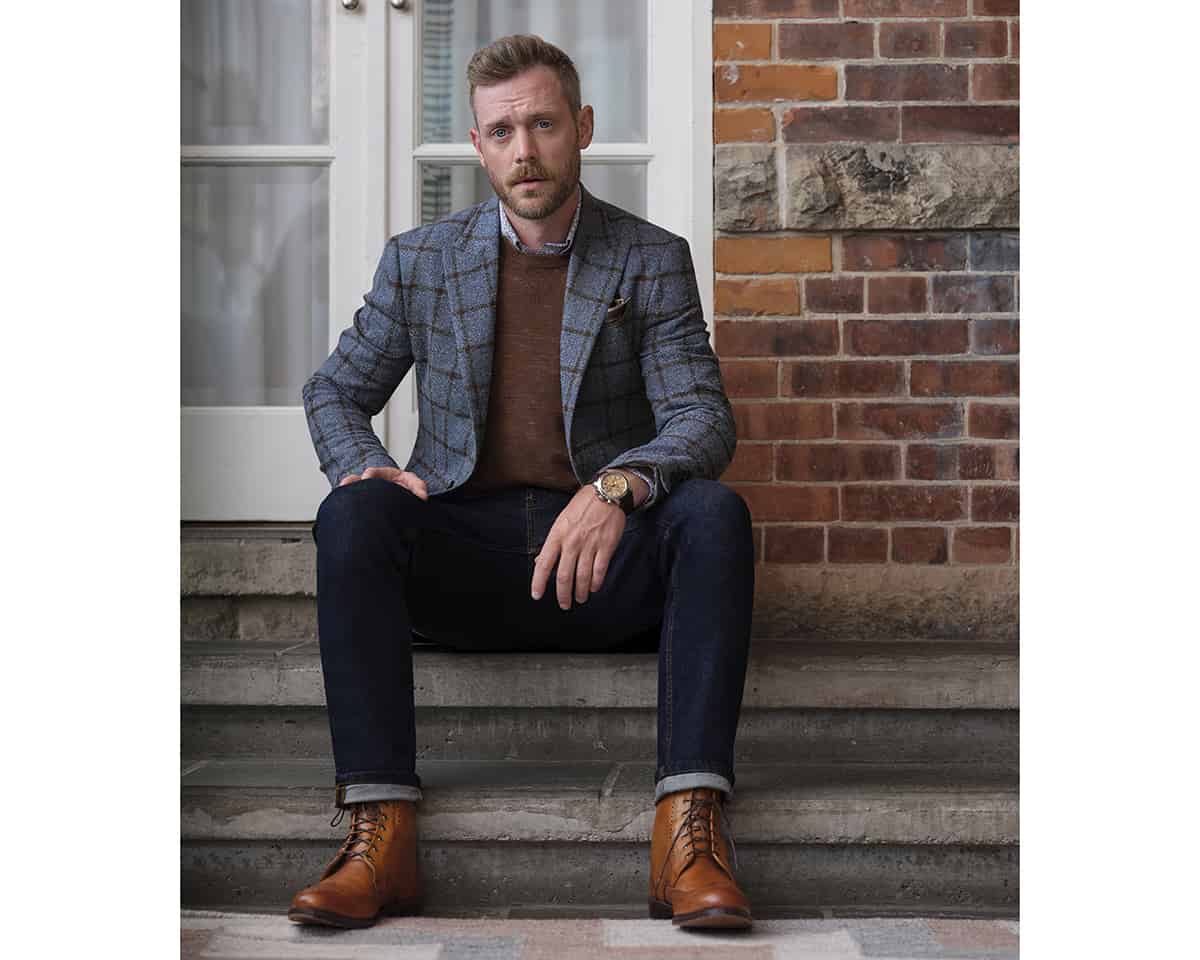

- More customers recognizing the value of wearing a sportcoat or utility jacket to complete the outfit (and hold wallets, keys, glasses). More marketing to reinforce this message could work wonders. We also need to better explain how to mix tailored pieces with sportswear.

Here, clothing makers share their crystal ball on tailored clothing: what’s happening and what’s needed.

Nelson Suriel, Jack Victor

The biggest change we’ve made over these past few years is going from a Montréal-based tailored clothing manufacturing company to a true lifestyle brand. In addition to our beautiful and high-quality suits/sport coats/trousers, we now offer sportswear (woven shirts, knit sweaters, polos, crewnecks and hoodies), accessories, and of course outerwear which we had launched before the pandemic. Our vision is to be a leading men’s lifestyle brand in the upper premium/accessible luxury segment.

I give Alan Victor all the credit: when the pandemic hit and most companies were in retraction mode, he chose to move forward and invest in new categories. We hired a creative director who designed and executed a beautiful cohesive collection with an emphasis on sustainability and responsible production throughout our supply chain.

For Fall ’22, what booked best for us was our Comfort Wear Collection, comprised entirely of jersey knits. The coat model boasts a super soft construction, butterfly lined with lower patch pockets, no shoulder pads, no sleeve heads and only a very light chest piece. The cost looks MONEY: perfectly clean – no breaks in the shoulders or collapsing chests. And of course, because of the nature of jersey, these coats move/stretch with the body. It’s like wearing a tailored sweater!

Also for spring ’23, we see a new emphasis on color and true seasonal fabrics. Even in suits, one of our best-sellers is a simple solid summer tan, great for spring/summer weddings and events.

I’m not in the fortune-telling business so it’s impossible to give you a five-year outlook; I’m a person who likes to live in the present. But my firm belief is that tailored clothing sales will remain strong throughout spring ’23. I know there’s a lot of “noise” about recessions and inflation but there are too many wedding/events on the books that were on hold for more than two years.

Stephen Granovsky, Samuelsohn

This is probably the most exciting and challenging time to be part of this industry in the 12 years we’ve owned tailored clothing companies. Demand for luxury menswear has intensified but supply is beset by a continued perfect storm of challenges: worker shortages, raw material shortages and cost increases.

Strategically, we’re addressing this by trying to find the right balance between short-term sacrifices to meet demand and long-term investments to serve our brands and businesses when the demand and supply realities pivot to a more “normal” environment.

Spring ’23 is about color and more color. We continue to see strength across all elements of our business, but we see a shift from basic and event-driven business to customers filling out their fashion wardrobes.

We believe tailored businesses will be strong for another 18-24 months before settling into a more normal demand pattern. However, the continued strength will come more from newness and less from basic black, navy and charcoal suits. This will also mean a further shift from off-the-rack to custom.

Tony Maddox, Coppley Apparel

We’ve done a bit of adjusting models, going back to our archives for a higher waistband trouser, but with a trimmer knee and bottom on some of the styles. We’ve also been exploring new fabrics: our in-stock basics were depleted so we’ve been looking for new fabric mills to partner with.

For example, after an early sales meeting for spring ’23, we’d requested goods (a 150s fabric) from a major mill and were told they can’t take any more orders since they’re already past capacity. This was after we’d made up samples for all our salesmen who were already taking orders from retailers. Apparently, the new president of that mill was focused on supplying their own stores and was less concerned about their wholesale partners. Fortunately, we found another mill that was able to take the order so we could make new samples for all our salesmen. And that sums up how it’s been going lately: we understand the shortage of raw materials, but we must be able to course correct. Our biggest concern is the reliability and consistency of new mill partners. We need to evaluate these partnerships to determine which are genuine so we can count on our strongest partners.

Other than that, things are fine! We’ve rehired our star production manager Roy Nichols (with Coppley for nine years) and we’re delighted to have him back to help us maximize our production capacity. We’ve added more color to the spring ’23 collection and we’re very excited about a focus on luxury (cashmere, alpaca) for fall ’23, with most sportscoats in the $895-$1595 range at retail. Our MTM business has been off the charts: we’d planned it down 10 percent for spring ’22, and it ended up being up 14 percent. Our custom business is up 20 percent vs 2019 and although we were unable to offer our typical 7-12-day turnaround, we promised stores three to five weeks and were able to deliver on that promise.

How to get more men to wear suits more often? I believe it must start with us: we in the industry must dress up more often! Even in Milan where I was for the recent fabric show, I’d say only 10 percent of men at the show were wearing suits.

Massimo Bizzocchi, Kiton

We continue to emphasize what we’ve always been famous for: luxury fabrics, quality craftsmanship and lightness of construction. Right now, the strength of our collection is our 1980s-inspired, softly constructed, single- and double-breasted in-house models.

Luxury fabrics remain our forte, capitalizing on more than five generations of trading fabrics. Our prices are honestly based on our quality and exclusivity (very limited quantities). Our distribution strategy, while limited, is to take care of our core customers while opening doors to stores that are searching for quality and exclusivity.

In terms of marketing, we’re paying attention to the evolution of the metaverse and to omnichannel opportunities. We believe that wherever the future takes us, tailored clothing will be an essential part of it.

Jasper Willems, Atelier Munro

A key change we’ve made recently is the addition of several new jacket models: safari, chore, utility, and a fabulous 2.5 button sportcoat with a more relaxed fit. Our focus is still made-to-measure, but we’ve added more ready-to-wear. This includes drawstring pants in both dress and casual fabrics, hybrid footwear (leather loafers on a sneaker sole), a full in-stock program of new luxury knitwear (merino, cashmere/silk) and more.

Price and supply chain issues are still challenging on the mill side: We now need to place orders far in advance so, although a huge risk, we placed early and aggressively for spring ’23 in both made-to-measure and RTW. We believe that despite lingering Covid worries, people will still go out and celebrate life. We’ve never seen so many groom parties for 10, 12, 24 people! Believe it or not, our best-selling suit for groomsmen is a three-piece wool/silk blend in a beautiful shade of green!

We’re very committed to partnering with North American stores. Although we believe that this business is based on personal contact, we’ve established a way for customers to reorder online once we have their measurements. We want the initial contact to be in a physical store (guys taking their own measurements is not a good idea), but the reorders can be online. We’ve created a system where the client can choose between deliver to his home or deliver to our partner store. The client pays online, and we immediately settle with the retailer.

How best to grow clothing business beyond events? Show customers that with new fabrics, new models and new technology, wearing a suit can be just as comfortable as wearing sportswear.

Jim Shay, Isaia

During Covid, we made many changes to the business, including opening stores in Miami, St Moritz, Chicago and Toronto. We also expanded our outerwear, leathers, and knitwear, buying upscale production facilities so we can produce our own fashion in our own factories. Also during Covid, we quadrupled down on casual categories: pj’s, robes, shorts, tees, product that sold well during Covid and is still selling well now.

But tailored clothing is back strong! In fact, stores were so overloaded with sweats and t-shirts that there was nowhere to go but back to tailored. So we returned to our core competency which is fashion sportcoats, where we’ve always been heavily penetrated. Our retail partners blew through what they had, selling more fashion than ever and chasing it now. So sportcoats and wedding suits: that’s most of the recent business. But as I like to tell retailers: don’t move all your dollars into a single category or a new trend will surely come along and kill it. Better to balance the mix.

I believe that to maximize the current tailored clothing trend, we need to give customers what they want but show it in a different way. We didn’t totally change our suit model, but loosened it up a bit so that the jacket is slightly longer and the pants, just a bit fuller. We’re not flipping our core, but we’re acknowledging a more relaxed silhouette in fashion.

As for price increases, we’ll be up about 8-10 percent in 2023. It’s no surprise to anyone: shipping costs have doubled; labor and raw materials are way up. But since we own our own factories, we’re just dealing with mill delays that are running four to five weeks.

If we as an industry really wanted to improve business, we’d push deliveries two and a half months to the right. I mean fall goods were already in the stores in the middle of a brutally hot summer! It’s ridiculous. But if the situation didn’t change during Covid when stores had little to lose against 2020 figures, it’s never likely to change. As a manufacturer, we need to mindful that goods delivered during transitional months are in fact transitional in weight.

Andrea Benedini, LBM and Luigi Bianchi

There’s new excitement in our Spring ’23 LBM 1911 collection: our typical shades of blues and neutrals are joined by a new emphasis on color, everything from a beautiful new green to cherry. This has given a fresh vibe to the collection.

For spring ’23, we’ve had strong reaction to many of our special cottons and linens. These are touch fabrics with a very soft hand, not just garment dyed but finished with an organic process to give a peached hand. The lightest fabrics with the least amount of construction—this is what customers want in our overheated world.

We also offer natural stretch fabrics, lots of jersey and several new shirt-jacket models. We’ve tried to keep an eye on pricing, offering in our LBM collection a good selection of exclusive fabrics at $795-$895 retails. For many of our retail partners, this has become a core business.

In our more sartorial division, Mark created for the U.S. market in-stock programs for suits ($1295-$1495), blazers and tuxedos. Travel jackets with inside vests have been very strong.

Most importantly, it was wonderful to see so many of our retail partners come into our New York showroom, ready to buy and in such good moods! This positive energy makes me very happy!