CELEBRATING WOMEN’S HISTORY MONTH WITH GLADSON NEW YORK AND HUDDERSFIELD FINE WORSTEDS, DAY TWO

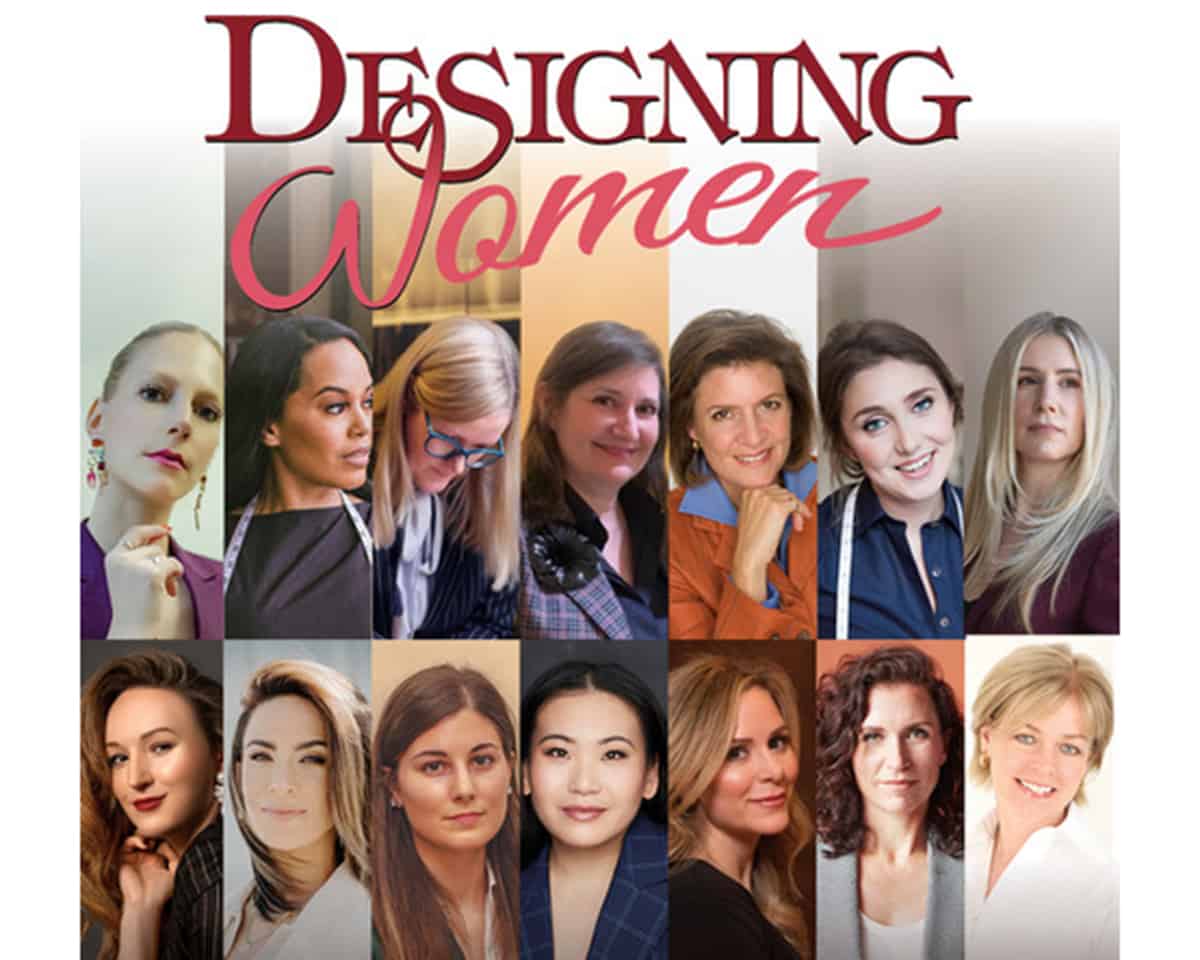

Gladson New York and its sister company Huddersfield Fine Worsteds, the Falconer Agency, and MR Magazine are celebrating Women’s History Month by shining a spotlight on a number of talented women designers, tailors, custom clothiers, and stylists who are making waves in custom clothing both here in the United States and on Savile Row in the United Kingdom.

Over the past twenty years, the industry has seen an exponential growth of women entering the menswear custom clothing market and they are doing very well. With a wink to the past, we call them “Designing Women” as an homage to the 1980s television sitcom, where power dressing, big hair, and big shoulder pads ruled the day.

Today we spotlight Lisa Bubes, of Garmentier, a company that helps stylists spend more time doing what they love, and less time on the ho-hum details of running a business. Mary Zarob, an F.I.T. graduate (go Tigers!), helps the stylish people of Phoenix, Arizona, build elegantly casual wardrobes, apropos of the city’s lifestyle. Finally, Emily Young Zimmerman is building her own empire of custom clothing with her company, Label, which is headquartered in New York City with four other locations nationwide.

As a side note, as the political landscape is shifting beneath our feet, American women and the LGBTQ community are seeing their human rights diminished day by day, state by state. Empowerment starts with feeling good about yourself and your message and dressing for success might just win the day.

Lisa Bubes

Garmentier

Chicago, Illinois

What brought you to tailoring/custom clothing?

I started as a personal stylist for men and expanded into custom clothing and tailoring. I’ve trained over 1,000 stylists and helped them grow both their custom tailoring and ready-to-wear businesses.

How would you describe your business?

Garmentier helps personal stylists a) run a super profitable, tech-forward styling business, and b) source and sell the best products, including custom-tailored clothing as well as premium ready-to-wear brands.

What is the makeup of your clientele?

Personal stylists. About 80% focus primarily on sourcing ready-to-wear pieces. 20% also design/measure/sell custom-tailored clothing.

What is the most rewarding part of your job?

Watching talented stylists start a new business and grow it to well over six figures in just a few years, through our technology and retail/custom partnerships. Simplifying access to independent stylists for our favorite retail brands and custom fabric mills/manufacturers. It’s gratifying to help both sides win.

What are the key stressors?

Technology in the retail apparel industry, especially custom tailoring and manufacturing, has not kept up with our growth. We’re a sophisticated platform with a great tech team, but we can’t build a custom solution for every vendor. You’d be surprised at how many are still using outdated third-party software or manual processes.

What distinguishes your business from the competition?

We help stylists and independent sellers/custom businesses earn more and serve their customers more holistically. Our operational support and business/styling tools are proven to help stylists grow their business from $0 to $300K+ individual annual income. We are the only platform that enables them to source/sell the best-possible products through any channel: online, in-store, try-before-you-buy boxes, and custom clothing.

From an industry perspective, what improvements are needed to make custom more profitable for you?

I’m biased since we are a technology company, but I would say technological improvements come first. We’ve got front-of-house operations covered with our seller tools and platform. But back-of-house technology needs revamping. Fabric mills should have standardized fabric libraries with real-time outs and open APIs, and manufacturer order entry systems must continue to improve. We can help the industry work through the second part, but the first part is out of our hands. A close second: fabric mills and factories should continue to expand their product offerings to include more relaxed, everyday garment styles. The mills and factories that adapt their manufacturing and fabric selection strategies to mirror consumer trends toward casual are guaranteed to experience a lot of growth in those categories over the coming years.

Now that we have entered a post-pandemic phase of Covid, have you needed to change your fashion models and/or your styling? If so, what’s been working well for you from a fabric, model and/or style perspective?

We’ve all had to shift to be able to offer more casual silhouettes. What’s important now is to combine quarterly research on consumer trends in retail with a better understanding of your client’s day-to-day lifestyle. Too often, I’ve seen sellers adopt a cookie-cutter style of selling.

What type of training or schooling was required for you to become a tailor and/or a custom clothier?

I was trained with a few hours of measuring practice by my former boss and mentor. I learned by measuring and making garments for my clients and hundreds of other stylists’ clients, with many mistakes along the way.

If you were to create a vision board that reflects your personal aspirations regarding your career, what might it look like?

The goal is to make it as easy as possible for consumers to look and feel amazing. That can be difficult today, with an overwhelming amount of products/brands and less guidance or community than ever. Whoever is solving these problems, I’m with you!

Mary Zarob

Phoenix, Arizona

What brought you to tailoring/custom clothing?

I studied menswear and tailoring at FIT and fell in love with it. I enjoyed learning from professors who were master tailors.

How would you describe your business?

I dress my clients for the moments that matter most, based on their needs and how they want to present themselves – from custom suits and shirts to casual golf attire and jeans.

What is the makeup of your clientele?

Professionals in all industries (age 28 and up) and their families.

What is the most rewarding part of your job?

Seeing my clients smile and hearing them share the compliments they get when wearing the clothes I make for them. Nothing tops that!

What are the key stressors?

Time management. I juggle a lot, from clients to inventory management to vendors.

What distinguishes your business from the competition?

My honesty and taste level. I help my clients build wardrobes they are excited to wear. If I don’t think something will look right, I tell them. I encourage them to buy pieces that push them a little bit out of their comfort zone. If they are looking for something t I don’t have, I advise them on where to shop. I want my clients to love their clothes. That’s more important than selling something from my shop.

Now that we have entered a post-pandemic phase of Covid, have you needed to change your fashion models and/or your styling?

My shop and clientele are in Arizona, where men and women dressed casually even before Covid. I’ve always carried casual pieces and made casual garments for my clients. My mill partners have supplied me with casual fabrics for a while. Covid helped me acquire more clients who want unique casual clothes and can’t find them at department stores.

What type of training or schooling was required for you to become a tailor and/or a custom clothier?

Anyone wanting to get into the industry should attend school but also find a great mentor/tailor. I learned more on the job from my mentors than you can learn in a classroom.

Emily Young Zimmerman

New York, Chicago, Austin, Charlotte, and Dallas

What brought you to tailoring/custom clothing?

My love of quality clothing and classic style comes from my father. He dressed well and was particular about every detail, including pressed denim over his cowboy boots. I started my custom clothing career at a well-known company, Tom James. A colleague there recruited me to help start Trunk Club Custom. Now I am at my fourth custom company, and I can’t think of an industry I’d rather be in.

How would you describe your business?

Label is a nine-year-old custom clothing business that offers a full wardrobe experience for men and women. We assist with styling, measuring, and wardrobe building. Our experts are trained in a consultative approach that makes shopping for clothes more enjoyable, whether or not the customer is a fashion connoisseur.

What is the makeup of your clientele?

Business professionals from various industries. Mostly men at this time, but we are seeing success with our women’s program.

What is the most rewarding part of your job?

Teaching others to do a job I love in an industry that brings together the old and the new. I also enjoy bringing sales and operations together for scalability.

What are the key stressors?

Keeping the team on track, and not being reactive to the building process.

What distinguishes your business from the competition?

We offer an elevated, full custom experience with quality products and superior fit. We don’t buy customers with promotions or gimmicks. Our sister brand, Alts, adds an alteration component in-house.

From an industry perspective, what improvements are needed to make custom more profitable for you?

Technology has always been a roadblock in this industry. Every maker and mill processes orders differently. Some still use email or non-standardized forms. Although some companies are trying to engineer solutions to this problem, there is no solution yet that fits the majority. We end up having to build CRMs and order entry platforms in-house, which is expensive.

Now that we have entered a post-pandemic phase of Covid, have you needed to change your fashion models and/or your styling? If so, what’s been working well for you from a fabric, model and/or style perspective?

During the pandemic, I worked for a different company that added sales channels through e-commerce, including partnering with well-known menswear retail brands. Working at a full custom company that does not sell ready-to-wear or use e-commerce has been more challenging. We’ve added more casual options, made-to-order for different models, and more accessories to fill in the assortment. We’ve done well with performance shirting fabrics and knit jacketing. Everyone wants to be comfortable.

What type of training or schooling was required for you to become a tailor and/or a custom clothier?

My direct sales background and willingness to work hard prepared me to become a custom clothier. I was trained in the craft by a world-renowned company. Learning from experts, traveling to mills, and independent study — along with my education in apparel merchandising — helped me to be successful. I used what I learned to create a training program for hundreds of salespeople.

If you were to create a vision board that reflects your personal aspirations regarding your career, what might it look like?

This industry needs more disruption! I visualize the coming together of fashion and function, with a higher level of service on both the consumer and wholesale sides of the business.

I would love to be the middle person, helping vendors and mills better understand the sales cycle and product training needs while also helping clothiers understand how to relationship sell. I look at this business holistically and get excited about the challenges.

My goal at Label is to build a large-scale men’s and women’s custom business throughout the US.