A BRIEF BUT SPECTACULAR HISTORY OF TAILORED CLOTHING WITH MICKEY SOLOMON

Trands USA hosted the latest edition of The Custom Show in Atlanta, GA, from February 19 to 21, at the Embassy Suites by Hilton Atlanta Buckhead. The show’s vendors and attendees were all invited to join what Trands’ Mark Thiele (above with Mickey Solomon) described as a day of “continuing education,” the same as any lawyer, doctor, or accountant might be required to attend. The morning session included a presentation by Gladson CEO Mickey Solomon about the history of the tailored clothing textile business, as well as his own approach to fabric design. I was lucky enough to spend several hours with Solomon preparing for the presentation, and you can only imagine the amount of detail that we ended up having to leave out to fit into our allotted time.

Mickey Solomon: 65 Years in the Business

Mickey Solomon: 65 Years in the Business

As regular readers of MR know, Mickey Solomon is an icon in our business. As Thiele put it, “In tailored clothing, we have icons like Ralph Lauren and Calvin Klein, but in the unbranded [custom clothing] part of the business, we have Mickey Solomon. He’s the force behind legendary fabric collections like Bamboo, and Flash.”

Solomon’s journey in this business began when he started working with his father at John Emsley Ltd, a worsted manufacturer based in Yorkshire, England. At the time, the company specialized in mohair and wool fabric, which was a big hit with the Rat Pack. He shared a brief timeline of how the textile business here in the United States developed.

The State of Tailored Clothing in the 1960s

The State of Tailored Clothing in the 1960s

Before the 1960s, the United States clothing industry relied primarily on domestic American-made goods and British imports. Domestic mills, such as Burlington, Stevens, and Forstmann, produced high-quality fabrics, but truly upscale goods were sourced from Britain. Italian textile mills hadn’t even entered the market yet. The landscape shifted dramatically when Japan, emerging from post-World War II reconstruction, developed a textile industry that closely mimicked British production. By the mid-1960s, this competition drove many domestic and British mills out of business, and by 1970, the cycle had progressed to Korea and, eventually, China.

The 1960s was the Golden Age of tailored clothing in the United States. The industry was booming—total suit consumption in the United States reached 22 to 23 million sleeve units, an astonishing figure given that the U.S. population was around 125 million at the time. Despite today’s larger population, those numbers are still unmatched. (Mickey shares that in even a small town of a few thousand people, several men’s specialty stores would sell suits. He even heard stories of men’s tailored clothing being sold at a local gas station.)

At the time, manufacturers discouraged custom tailoring, preferring to focus on mass production. Only a handful of high-end manufacturers, such as Hickey Freeman and Oxford Clothes, would accommodate custom orders.

The Italian Influence and the Shift in Fabric Production

The Italian Influence and the Shift in Fabric Production

A major turning point came in the 1980s when Italian mills, particularly those based in Biella, began making inroads into the U.S. market. Unlike Asian mills, who required bulk orders of 300 to 800 yards per color, the Italians introduced the concept of “collections.” They curated selections of fabrics designed to appeal to global customers, with significantly lower minimum order requirements. This flexibility allowed retailers and designers to experiment with new designs and patterns without committing to large quantities. Over the past 40 years, this model has become the industry standard, with Italy now serving as the primary source for premium fabrics.

Before designer branding took over the industry, clothing factories were the most recognized names in the business. Brands such as Hickey Freeman, Hart Schaffner Marx, and Hammonton Park dominated the market. Attempts by designers to break into the tailored clothing sector initially failed. Even Pierre Cardin, one of the most influential designers of his time, struggled to make an impact. Hammonton Park attempted to create a collection with Ungaro, who was a trained tailor, but it didn’t work. This all changed in the late 1970s with the success of Saturday Night Fever’s notorious white suits, designed and made in France by Pierre Cardin for Intercontinental Brands. This era marked the rise of designer brands in tailored clothing, with names like Calvin Klein, Ralph Lauren, and Zegna emerging as industry leaders.

Designing Fabrics: Balancing Innovation and Practicality

As Solomon explains, “There is a certain romance attached to fabric design, but practicality remains the highest priority. A designer has a responsibility to the mills to ensure they stay in business! While creativity and new ideas are important, it is crucial to consider what a mill can realistically produce. What have they produced historically? What are they comfortable producing?”

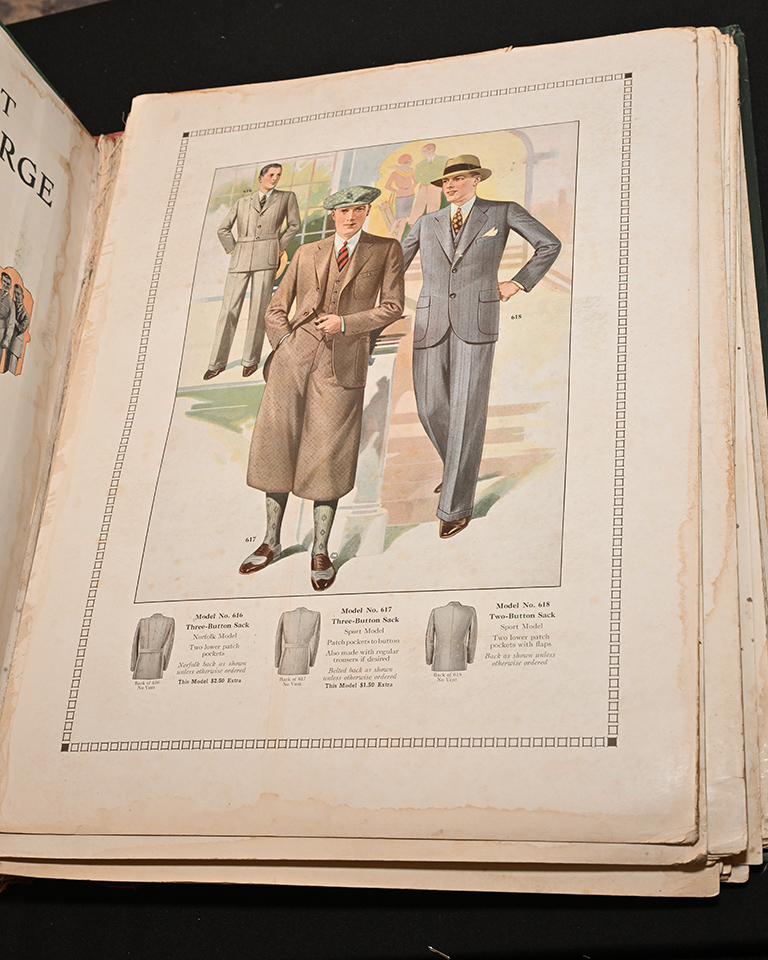

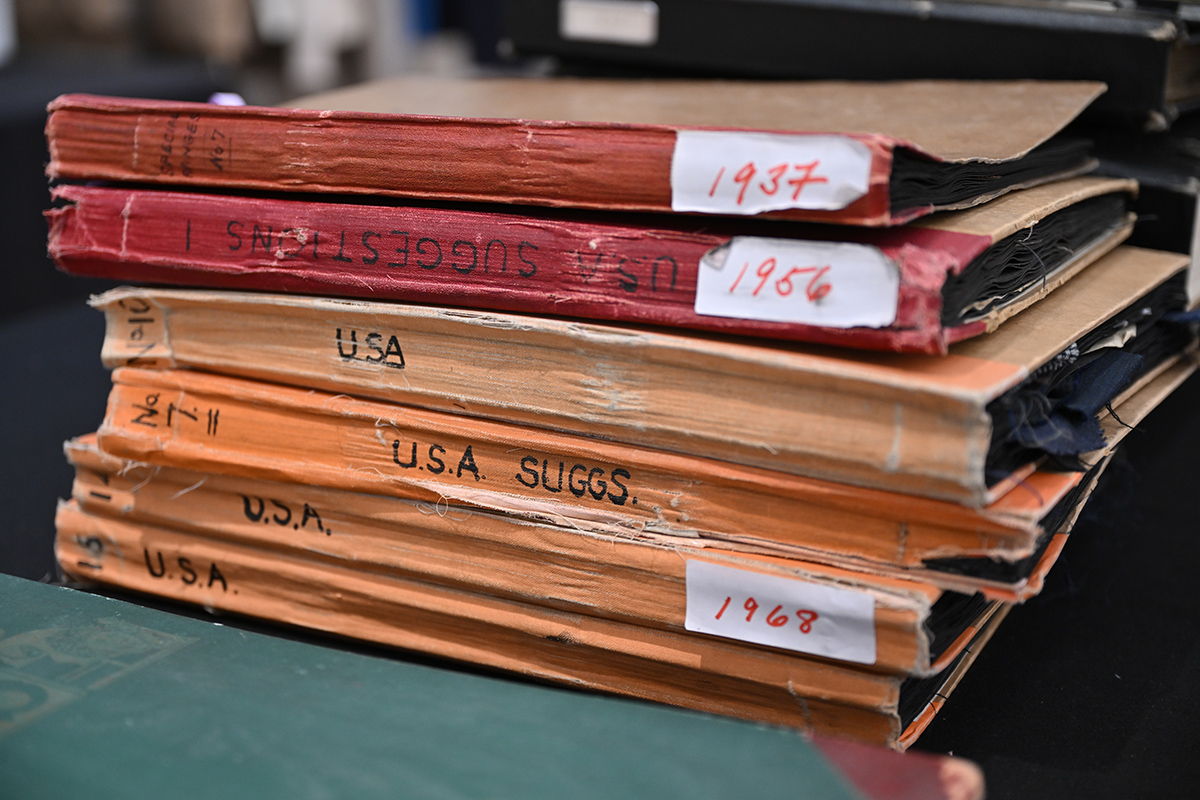

“Many fabric designers reference archive books dating back 75 to 100 years, but I prefer to look at designs in ten-year increments to observe how styles evolve over time,” says Solomon.” For example, we went through a long period where stripes dominated, but about 15 years ago, plaids became the preferred pattern.”

The foundation of any tailored garment is its fabric. “Most of what we work with are existing fabrications—what are the wool grades, yarn counts, and weight specifications that the mill already produces? We can do some experimenting with fabric composition, such as adding stretch or cashmere, but that requires extensive research and development.

The Importance of Patterns and Colors

The Importance of Patterns and Colors

Patterns and color selections are dictated by market research. Again, it’s about that feedback from retailers, but it’s also about looking at European trends, especially on Milan’s Via Montenapoleone. “The Rinascente department store practically has practically every designer.

“Global variations in taste mean that designs have to be tailored to specific markets, and what sells in Italy won’t appeal to American consumers, making it essential for us to develop our own designs rather than relying solely on European collections.

“Once patterns are selected, we move to the color phase. Each warp and weft color must be chosen carefully, and we provide mills with precise design layouts. Traditionally, this process was done by hand, but advancements in computer-aided design (CAD) have streamlined it. While CAD technology has improved significantly, there are still limitations, particularly in accurately capturing fabric textures. From CADs, we proceed to fabric “blankets”—physical samples that allow us to refine colors and patterns before final production.”

Unfortunately, time constraints left us right about here with Mickey Solomon’s historical recap and design process. There was probably enough left unsaid to fill a 30 to 40-hour learning seminar.

Tomorrow, we’ll recap The Custom Show’s panel discussion, which was chock-full of great ideas for customer service and both brand- and business-building techniques.

All photos courtesy of Gladson by @kimevansphotos

Mickey Solomon: 65 Years in the Business

Mickey Solomon: 65 Years in the Business The State of Tailored Clothing in the 1960s

The State of Tailored Clothing in the 1960s The Italian Influence and the Shift in Fabric Production

The Italian Influence and the Shift in Fabric Production The Importance of Patterns and Colors

The Importance of Patterns and Colors

Mickey’s session was an additional highlight of The Custom Show. Always great to add to our education for an industry we love.