SHOWCASING BEST OF BRITAIN FABRICS: HOW THESE BEAUTIFUL CLOTHS CAN BOOST YOUR BOTTOM LINE.

In our new hybrid work environment, those of us returning to the office and face-to-face meetings are longing to look good again. Of course, “looking good” means different things to different people. For professional men and those aspiring to be, it usually means wearing a suit or sportcoat, with comfort now a prerequisite.

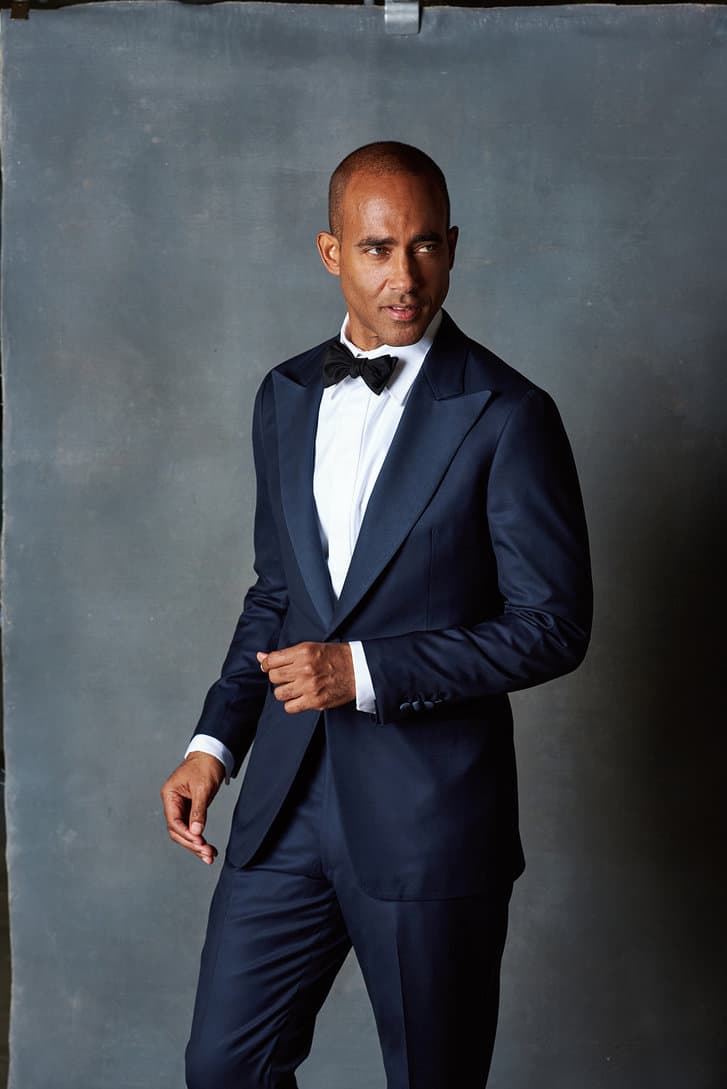

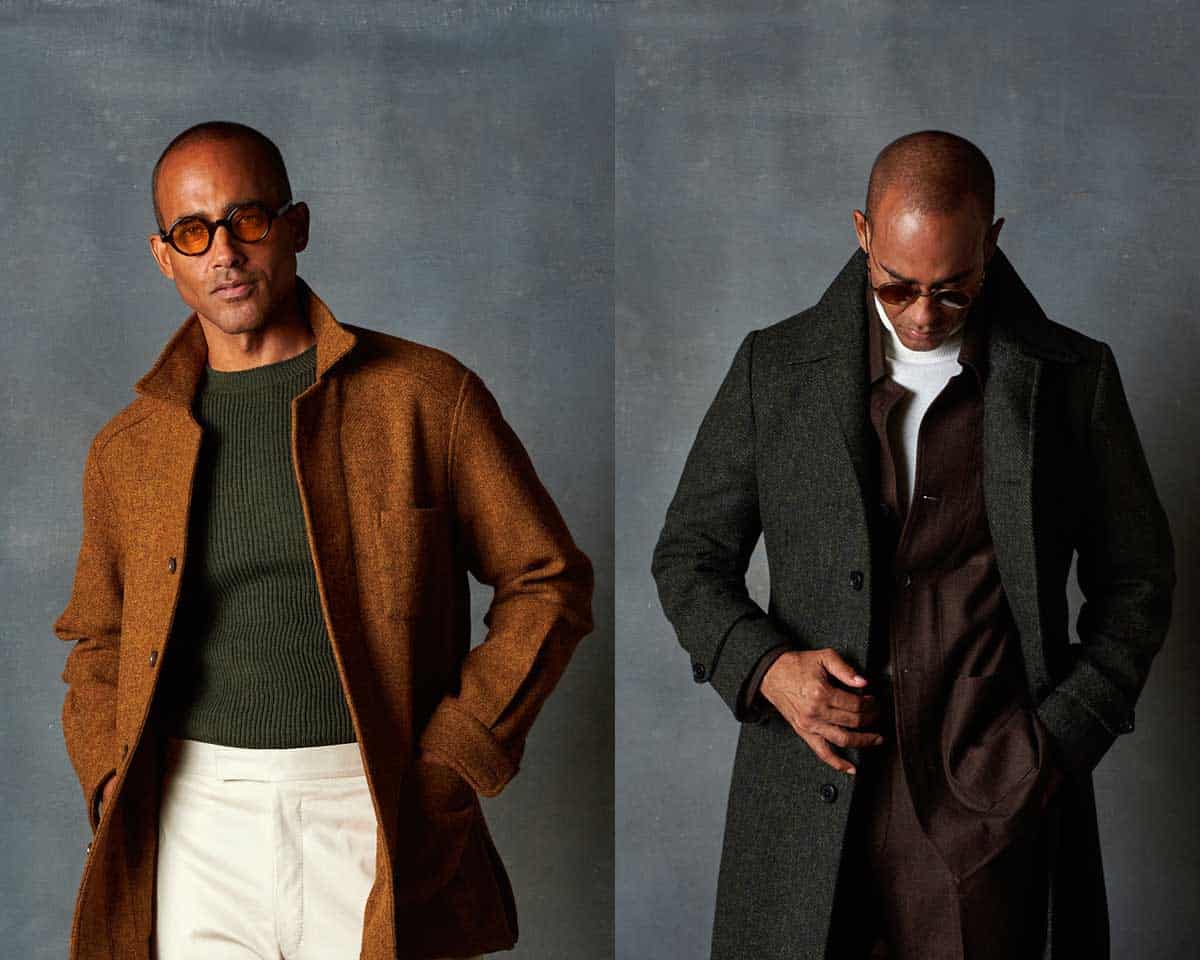

Dan Trepanier, founder and CEO of online custom clothing business Articles of Style, chose British fabrics from Gladson’s portfolio of heritage-inspired offerings for both his bespoke Made in America garments as well as for a new Made-to-Order offering just introduced. “This collection combines comfort and style with the quality and craftsmanship of fine menswear fabrics,” explains the press release from Gladson’s PR Falconer Agency. “Every piece in the collection is created in the USA from cloth manufactured at Huddersfield Fine Worsteds, Gladson’s internationally renowned mill in Huddersfield, England.”

In these excerpts from a recent roundtable, MR talks to Trepanier and the Gladson team (Mickey Solomon, Guy Milinazzo and Faith Wozniak) to learn more about British fabrics and the new clothing options for the coming season.

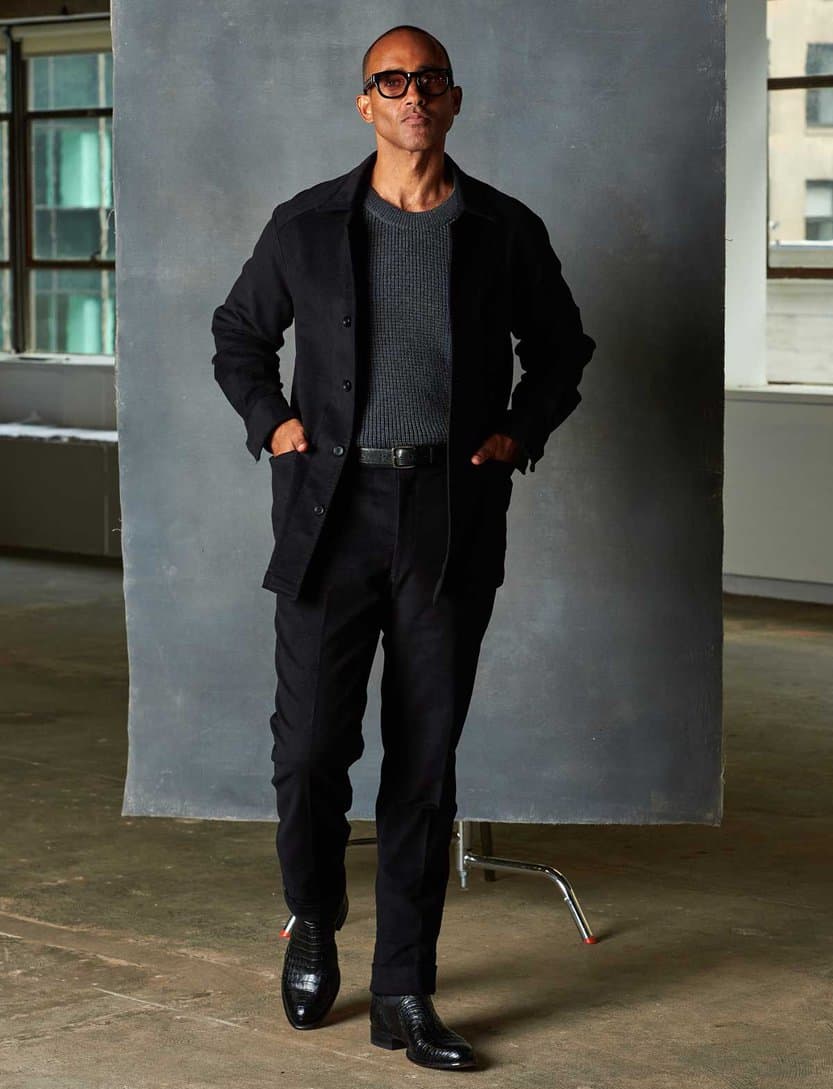

Dan: I founded my business to help men build wardrobes that endure through changing fashion cycles. I’ve always loved the look and feel, the durability and wearability, of British fabrics. I thought that if I could modernize the way our grandfathers dressed, maintaining respect for the heritage but with a casually elegant focus, I would attract new customers. And it worked! The average age of my customers is mid-30s. These guys love the timeless style of British fabrics in updated classic models. I teach them to add flair with accessories, not with foundation pieces.

Faith: British fabrics have a heritage that goes back centuries. Before Gladson acquired Huddersfield Fine Worsteds in 2009, it was a conglomeration of a half-dozen of Britain’s finest mills. One of our mills dates back to the 1300s! Today, British fabrics are a major portion of our portfolio. Our goal in showcasing these fabrics is to educate custom clothiers, designers, upscale retailers, and consumers about the legacy and benefits of British wool.

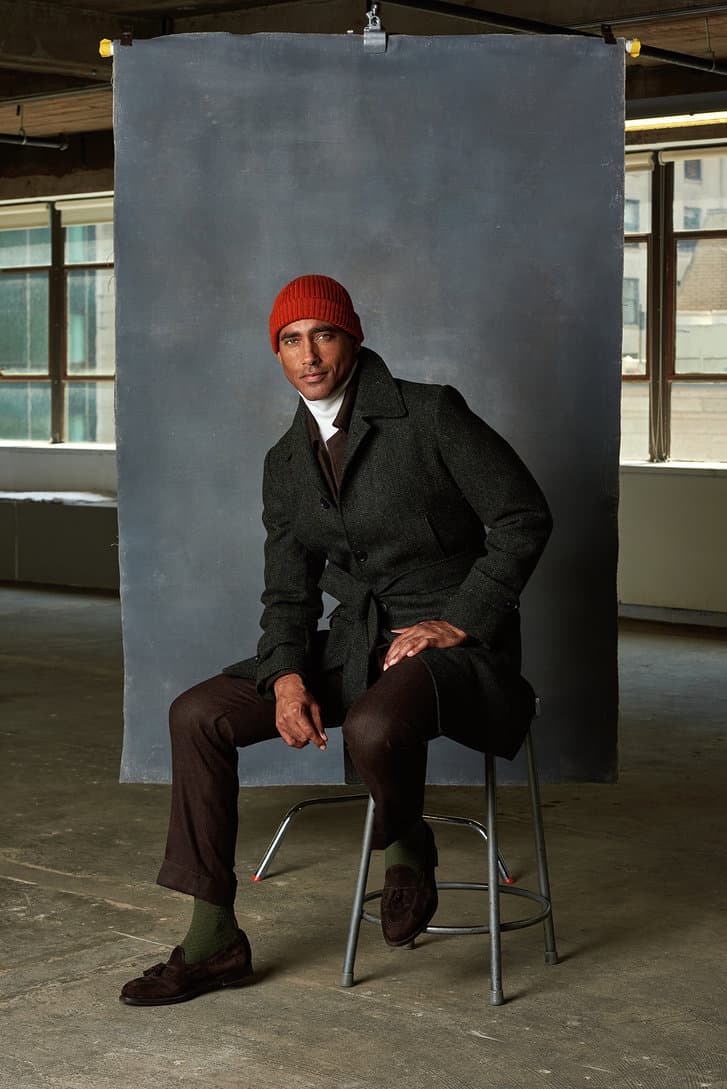

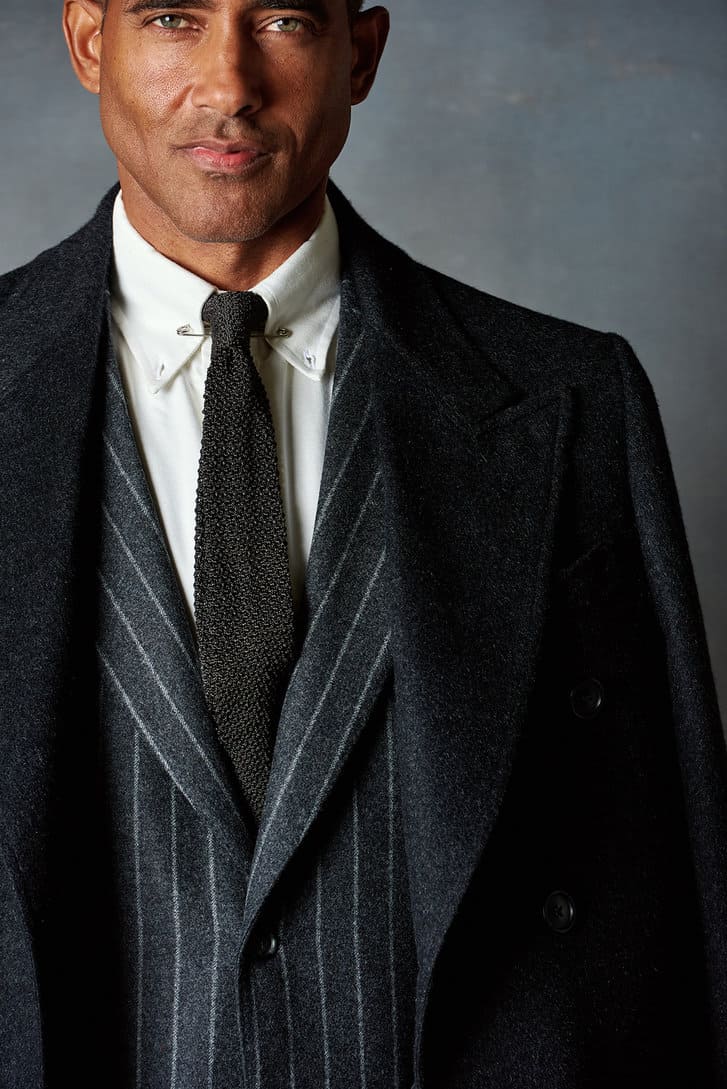

Mickey: British mills are known for traditional fabrics such as robust flannels, “gamekeeper” tweeds, twist sportcoatings (favored by European university students), Donegals, Shetlands, Harris tweeds, and authentic cavalry twills and coverts. All of these are made with heavier, thicker yarns and coarser wool than the typical fine worsted suiting. But it’s also true that from the end of World War II until about 1980, fine British worsteds dominated the luxury suiting market in the U.S. These fabrics continue to be the main production of British worsted mills.

There’s a big difference between woolens (with shorter fibers that crimp and create a thicker, twisted yarn) and worsteds (with longer fibers that can be combed and spun into fine yarns). These intrinsic differences give character to the yarns. For example, our gamekeeper fabric is an 18-ounce indestructible tweed used in outerwear. These coats last for 25 years and more. After a few decades of wear, customers bring the coat to their tailor to replace the lining. Fresco®, our best-selling fabric globally, is a coarse wool spun into a very high-twist yarn that gives it spring, recovery and a little ‘bite.’ Interestingly, this crisp, hard fabric is most appreciated by the Italians. One of the Italian mill owners placed a big personal order for Fresco fabric that he keeps in his home, declaring that it ages like fine wine!

Mickey: The woolen and worsted textile industry in the U.K. is uniquely positioned to satisfy the ever changing, sometimes specialized needs of the U.S. market. The operative word here is flexibility. British mills can make small quantities and custom yarns with a variety of fibers, sometimes using very fine wool to spin thicker yarns and generally using the hearty “English sett” and two-ply, both ways construction to weave their fabrics.

Dan: Many of them care a lot. We have two kinds of clients: the connoisseur customer who wants to know all about the history of the mills and how the fabrics are sourced, produced and finished. And the less sophisticated shopper who will buy what the seller tells him to buy. That’s why it’s so important to educate our sellers.

In today’s world of men’s fashion, there’s the Logo Culture that promotes whatever is deemed to be cool at the moment. And then there’s a culture of Timeless Style (think Steve McQueen), geared to the other 95 percent of us. The goal of many clothing designers today is to make the navy suit you bought this year look dated by next year. Our goal is to create lasting wardrobes that reflect the wearer’s personality and style.

Dan: Pants are a bit looser, lapels a bit wider (from 3.25 inches to 3.5 or 3.75 for peak), personally, I’ve always worn a looser bottom, now about 20 inches. I like a tailored garment to have some air, to move on the body. It’s much more elegant than painted-on pants. To me, too-tight clothing lacks nuance.

Guy: Dan has always known how to take iconic classic fabrics and make them cool. He understands the intrinsic character of different cloths. This collaboration has been a pleasure, as we are constantly learning from each other.

Mickey: I believe MTM will continue to grow. Since Casual Fridays, suit separates have been replacing nested suits. It’s risky for retailers to hang expensive nested suits on their selling floor; the markdowns are high and the turnover low. Upscale nested suits have given way to made-to-measure clothing; retailers and tailors can now offer creative options without getting stuck with inventory.

Dan: Custom is better for business and better for the environment. A lot of our marketing these days is focused on timelessness and longevity: create your perfect garment and wear it often for as long as possible. I love when I pull out a suit or sportcoat from the back of my closet and find an old ticket or program in the pocket that brings back memories. With fast fashion, our intimate relationship with our clothing has been lost.

Dan: There’s an unstructured moleskin suit that’s soft, dense, durable and super-wearable. I love the pleated trousers in Fresco fabric and the perfect Harris tweed peacoat—a forever piece that’s a great investment. Actually, all the outerwear pieces are fantastic! This has been such an exciting project for me because I’m creating the best possible garments in the most fabulous fabrics.

Guy: Mills have been paying more for energy, which accounts for some of the increases, but prices on their bread-and-butter legacy fabrics remain relatively stable. I even believe we’ll start seeing prices come down as mills produce more efficiently. As for supply chain issues, we’ve started bulking up, ordering ahead of schedule because the mills have been cutting seasons short. It’s painful now but should prove helpful later.

Mickey, what does the future of British fabrics look like to you?

The future looks very promising. Today, we can custom-create fabrics from the fiber itself, most recently developing blends with stretch. It’s all about the specific character, the flavor, the personality of the fabrics. Many retailers today don’t recognize that there’s a whole world beyond super 120s, 150s, 180s. I see a future for heavier luxury wools: 12–13-ounce worsted suiting that feels like cashmere. It sure beats freezing on snowy city streets in 9-ounce trousers!

View the collection: https://articlesofstyle.com/

Learn more about Gladson’s British cloth: https://www.gladsonltd.com/

For PR and Media inquiries contact: heather@falconeragency.com

For Sales inquiries contact: sales@gladsonltd.com

The 60’s/70’s brought the British Invasion of fashion to America. The 80’s/90’s The Italians ruled. Then in the new millennium, The Americans brought back natural shoulder clothing but with slightly higher button stances, higher gorged lapels, shorter coats and low-waisted pants with peg legs. The look was decidedly fresh and new but prepubescent. The time for Peter Pan is over- Thank God! Time for men to dress like men again. That said, these elegant, heavier British collections of cloth have a limited appeal in an ever-increasing climate-controlled environment in the city. They work north of the 41st latitude- south of that, not so much between March and November.