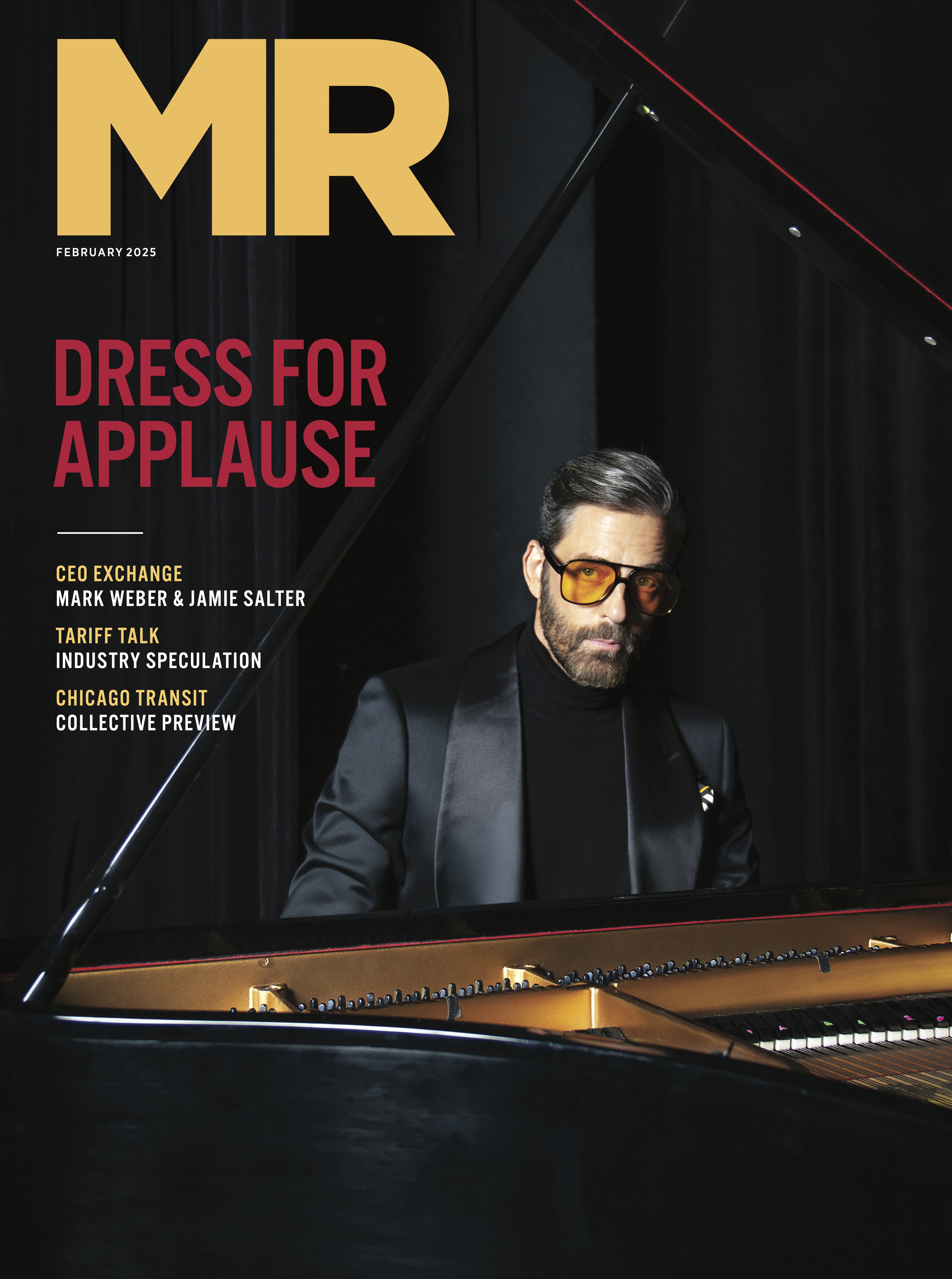

Speaking with style: Joe Dixon, SVP of production, Brooks Brothers

Many brands build on their heritage to create the meaning and authenticity increasingly craved by consumers. Yet for iconic US retailer Brooks Brothers, the idea of provenance extends globally, with a focus on bringing best-in-class products from around the world to US consumers. As the company expands internationally, Brooks Brothers’ SVP of production and technical services, Joe Dixon, spoke to Petah Marian about how its strategy is changing.

Joe Dixon joined Brook Brothers when it was bought by Marks & Spencer in 1988, and stayed on when the British retailer sold the brand three years later.

The retailer started life in 1818 as a vehicle for selling British goods in the US. “As the company evolved and became more American, and as Americans found their own style, we maintained those relationships, not necessarily in garments, but definitely in fabrics, and in quintessentially British products like gloves, scarves and briefcases,” he explains.

Dixon’s focus has been on differentiating the brand from the competition by using “our expertise to find products that are best in class, that are unique, and if we can make them exclusive to us, then all the better.”

“My job is to source from the four corners of the earth and to bring back special products for the customer. Sometimes that means finding ingredients and combining them to make a product,” he says.

For instance, in November the retailer ran an event spotlighting Scotland, including a celebration of Scottish textiles and its relationship with Scottish knitwear and fabric mills like Robert Noble, Barrie, Hawick Knitwear, Reid & Taylor, Harris Tweed, Todd & Duncan, Johnstons of Elgin and Begg Scotland.

The event involved Scottish-themed windows in the company’s Madison Avenue flagship, a shop-in-shop featuring other Scottish-made products, and in-store events – and a special tartan designed expressly for Brooks Brothers.

Another example of how the company works on combining best-in-class elements to make something unique is its non-iron shirt range. This, Dixon says, was probably the first 100% cotton non-iron shirt line launched in the US, and is now the company’s most popular item, with sales on track to exceed 6m pieces globally this year.

“We worked with a Japanese company that does clever things with yarn, clever things with fabric, we’ve combined it with a Hong Kong-based Malaysian company who have a great process, we worked with them for 18 months to perfect it, and then we brought to market this 100% cotton non-iron shirt.”

Global ambitions

While the company’s initial raison d’être was to bring the best of the world to America, the biggest challenge as it grows globally is to bring the best of the world to the world, without losing its DNA.

“How do we stay relevant in all these different countries?” Dixon asks. “When we go into Europe, we can’t sell an American trouser because it’s too baggy, and in Italy, you can only sell something that’s extremely form fitting and tight. But you can’t sell those products in the US.”

In this particular situation, the company has found a middle way – a slimmer fitting trouser that is perhaps not as tight as one would traditionally find in Italy, but still translates and remains true to the brand’s values.

The outcome of this debate was the Milano trouser, which Dixon says sells “enormously well” in Canada, and showed the company that slim fit and extremely slim fit, categories which it thought it wouldn’t be able to do, are now the “biggest selling categories we have”.

Made in the USA

This idea of taking an iconic US brand abroad is reflected in its sourcing strategy, with Brooks Brothers building its capacity in the US after buying Southwick, one of its suit suppliers, three years ago.

“I think the strategy will turn out to be pure genius, because if we can make that suit the best suit in North America, which it is close to being, and then if we can make it the best suit in the world, which is a tall order, then we have an iconic product we can export all over the world,” he says.

“So I think [that while] talk of bringing American factories online to support America is overrated, I think bringing phenomenal American quality products, and exporting them because they have the ‘made in America’ cachet, is a real possibility.”

Made in China

Yet for all the stories about provenance and discussion about origin, China and the Far East remain a key element in Brooks Brothers’ sourcing strategy.

The Far East and China in particular will remain an important sourcing country for the brand in the future, and Dixon has no plans to follow trends that see suppliers looking for cheaper and cheaper alternatives.

“We made a conscious decision, that unless we really saw the need, we weren’t really going to run [away] startled. And it’s not just about price. Some of the product we get from China is the best that money can buy, it’s best for service, close to fabric sources, we get great innovation, and we get people who reply immediately and understand us.

“I’m actually delighted to see some of the big players move away, because it leaves more capacity for me. So we don’t have to be so worried. We aren’t trying to buy a 50 cent jean.”

The company believes very strongly in long-term relationships with its suppliers – with 85% of its product coming from its top 10 suppliers.

“We have incredibly long-term and deep relationships and we value the special products that these relationships enable.”

“Early in my career a man much wiser and more far sighted than me once said: ‘we are a manufacturer without factories and our suppliers are retailers without stores.’ This helps create and sustain quality and innovation we try not to forget that we are only as good as the last product you brought from us!”